The risk of actual (and perceived) provenance issues

Provenance of products and raw materials is a key risk factor for any manufacturer. It is essential that companies have appropriate governance measures for their supply chains (and downstream distribution) and have action plans for dealing with disruption to supply and/or sales.

Summary: There have been 141 childhood deaths from Acute Kidney Injury (AKI) in Indonesia. The cause is thought to be high levels of ethylene glycol and diethylene glycol in some syrup-based medicines although not confirmed. It is suspected that medicinal raw ingredients (i.e. the supply chain) are to blame. We look at three case studies of other supply chain / raw material issues - milk, shampoo and luggage.

Why this is important: Other products may be impacted, both those containing the suspect medicinal raw ingredients and others if the manufacturing process of those ingredients is compromised and impacts other ingredients too. Liability could be far reaching.

The big theme: Provenance of products and raw materials is a key risk factor for any manufacturer. It is essential that companies have appropriate governance measures for their supply chains (and downstream distribution) and have action plans for dealing with disruption to supply and/or sales.

The details

Between 2008 and 2015, whilst working at Morgan Stanley, I was focused on the Asia markets, from India in the West to Australia and New Zealand in the East; from the ASEAN countries in the South to Mongolia and Japan in the North.

At the time, outsourcing was accelerating and the commodities supercycle was in full swing with rising demand from emerging markets and the BRIC countries (Brazil, Russia, India and China). This meant that supply chains grew rapidly and in many cases opaquely giving rise to a number of scandals across different industries. From milk to shampoo to suitcases. We shall discuss those later.

In a recent story, simple cough medicine may have contributed to childhood deaths with the issues potentially arising from the pharmaceutical supply chain.

The big theme

Provenance of products and raw materials is a key risk factor for any manufacturer. It is essential that companies have appropriate governance measures for their supply chains (and downstream distribution) and have action plans for dealing with disruption to supply and/or sales.

Acute Kidney Injury and cough syrup

There have been 141 childhood deaths from Acute Kidney Injury (AKI) in Indonesia. A separate article reported that there have been more than 240 cases of acute kidney injury in children in Indonesia across 22 provinces with the majority of cases amongst children under five years old.

The cause is thought to be high levels of ethylene glycol and diethylene glycol in some syrup-based medicines although not confirmed. Gambia saw at least 70 child AKI deaths in similar fashion. Health Minister Budi Gunadi Sadikin commented that changes in raw ingredients recently were likely to blame although this has not been verified. China and India are the chief exporters of medicinal raw ingredients to Indonesia. It has been separately reported that all syrup-based medications have been temporarily banned in addition to five locally-made products.

Indonesia’s Food and Drug Agency (BPOM) is considering prosecuting two as yet unnamed pharmaceutical firms.

Let's look at why this is important...

Why this is important

A key issue in this story was provenance of supply. The further one gets outside of an organisation into the value chain both upstream and downstream, the less control and assurance a business naturally has over activities, intermediary products and raw materials and unexpected events. This is why governance is so important.

Policies and procedures have been, and will continue to be important, but there are also technological innovations that could help. Traceability is a crucial component in guaranteeing provenance and sustainability through a supply chain.

Traceability

Consumers are increasingly demanding more information about where their products are from and how they’re manufactured. Innovations in authentication technology are providing an added layer of transparency, whether that be with the use of blockchain or digital tagging.

However there is a 'garbage in, garbage out' risk. Normally, only verified parties can contribute to a private blockchain network but if false information is given at the source, it’s difficult to spot this further down the chain.

Molecular-based technology, however, is harder to falsify and DNA tracing is a particularly exciting development as it tackles this issue at a molecular level.

Back in 2014, an Oregon laboratory was tasked with proving the origin of a shipment of rosewood logs that arrived at a Sri Lankan port. After examining a sample, it was determined that the logs possessed the chemical signature of rosewood species found in Madagascar, one that was illegal to export at that time.

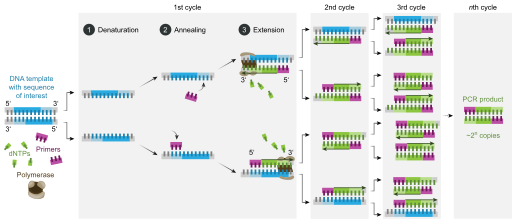

One example in the seafood industry is from Thai Union who launched a forensic science and DNA technology-based product to tackle food fraud with single Nucleotide Polymorphisms analysis and DNA barcoding. Fish samples are sent to the firm’s Global Innovation Centre laboratory for DNA extraction and polymerase chain reaction (PCR) analysis to compare it with a database, before it is checked for species and origin ID.

DNA technology-based solutions do have issues though too. The process relies on samples for comparisons so to have a comprehensive system across aquaculture and agriculture would require an immense operation to gather samples for every species. Results can be generated in seconds, but it’s likely the method will need time to fulfil its full potential.

There are non-biological alternatives too. Bunkertrace uses oligonucleotides (short single strands of synthetic DNA) to tag bunker fuels (used in shipping) by providing a unique and secure code which acts as a fingerprint to embed information on quality and origin. Sensitive molecular flags are employed to detect whether a product has been altered.

Another traceability tool is Satellite technology, one which Thai Union has also piloted. The trial involves their partner Sea Warden applying AI and machine learning techniques to generate data insights from 24 months of production activity across multiple shrimp farms.

Human rights in the supply chain

Another area of increasing focus is human rights abuses. The risk is exacerbated in industries with a reliance on mined commodities where locations are remote and may be in undemocratic regimes. The growth in contract manufacturing where outsourcing is typically in lower labour cost countries is another risk factor as cost pressure can lead to corners being cut.

The International Labour Organization (ILO), the International Organization for Migration (IOM) and Walk Free released a report recently estimating that there are 50 million people in situations of 'modern slavery' on any given day. The Sustainable Investor writer Kristina Touzenis discusses this in a Daily Perspective.

This is no longer a values-based issue, breaches can also have a financial dimension. Moves such as the upcoming German supply chain law (Lieferkettengesetz) mean that companies will need to “perform various due diligence procedures in order to monitor, prevent and ameliorate potential human rights abuses in their supply chains.” And courts are increasingly willing to impose a common law duty of care on parent companies for the wrongful acts of their international subsidiaries.

So having strong policies, procedures and technology in place can help to provide a strong governance environment around a business's supply chain. Stakeholders are increasingly considering the business as part of the broader ecosystem and are less inclined to absolve a business for 'sins of the connected.' A great example is that of 'scope 3' emissions where the consideration and disclosure by a business of not only its own directly generated GHG emissions but also those of its supply chain are crystallising in law and standards.

So having a strong governance environment around one's supply chain is important. Equally as important from a market value perspective is how a business responds when supply chain disruption and issues happen, both operationally and from a communications perspective.

I am reminded of three scandals from my time living in Hong Kong that are a further reminder of the importance of strong governance and planning with supply chain. All were health related, but with different causes, from different industries, handled in different ways and leading to very different outcomes for the stocks.

Case study #1: The melamine scandal

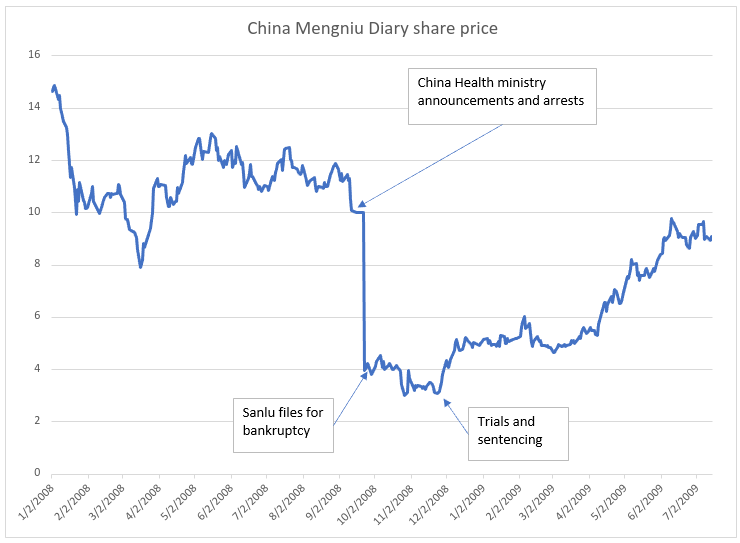

The 2008 melamine scandal that hit the entire milk industry both domestic and foreign producers led to significant prosecutions (including two death penalties) after more than 50,000 children were hospitalised with resulting kidney stones and other damage.

Milk production was and remains fragmented with many individual farmers producing milk from their cows but a smaller number of large companies such as Sanlu (which New Zealand dairy company Fonterra had a 43% stake in) and China Mengniu Dairy marketing and selling milk and derivative products such as baby formula, yoghurts and desserts.

Middle-men emerged to collate milk from individual farms and then sell, at a mark-up, to the larger organisations. Watering down of milk became a common practice to bolster volumes and in order to fool protein tests, certain unscrupulous agents began adding melamine, a nitrogen-rich compound, to the milk. The problem was exacerbated as intense competition in the milk industry squeezed procurement processes, in particular for Sanlu.

On 17 September 2008, China Health Minister Chen Zhu announced that tainted milk formula had "sickened more than 6,200 children, and that more than 1,300 others, mostly newborns, remain hospitalised with 158 suffering from acute kidney failure" which triggered a number of arrests including Sanlu executives.

On 27 September 2008 Sanlu went bankrupt. A speedy trial in December 2008 resulted in death sentences for a Hebei farmer and a manager of a milk production intermediary as well as lengthy jail terms including for the Sanlu general manager.

Case study #2: Bawang shampoo

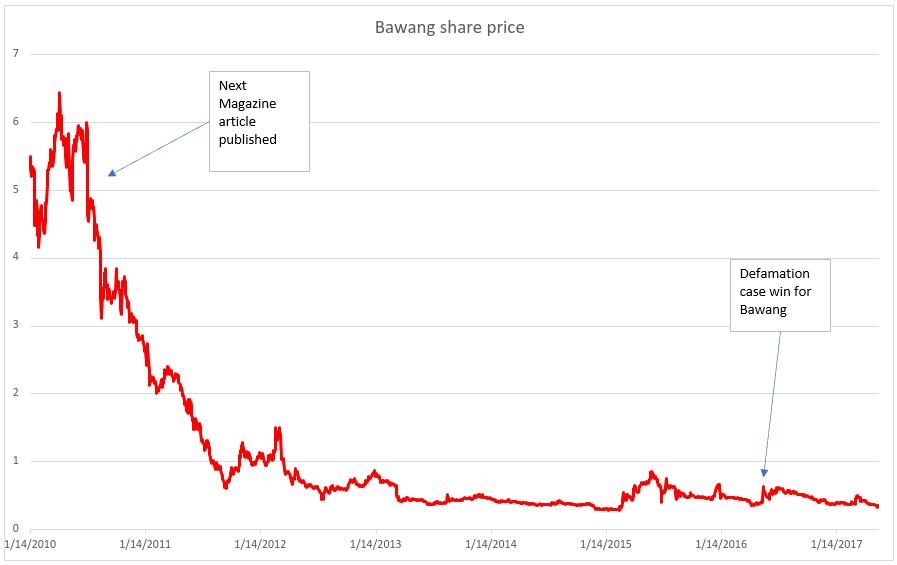

In 2010, Bawang shampoo was claimed to contain cancer-causing chemicals. Whilst strictly speaking true, the levels were not dangerous or particularly different to any foaming product. However, a lacklustre, almost dismissive response from the company led to share price and market share decline that the company never recovered from.

An article was published by Next Magazine on July 14 2010 claiming that Bawang shampoo contained dioxane, a chemical classified by the International agency for Research on Cancer as a carcinogen. Bawang highlighted that the concentrations of the chemical were "far below the saftey limits" and not only that, the chemical was present in most foaming products at the time. As such the company felt confident that the claim was without merit and looked at taking legal action.

However the public response was fairly immediate. Traditional Chinese Medicine practitioners took full advantage, even as Bawang shampoo had been billed as a 'herbal' product - something that led to endorsement by Hong Kong superstar Jackie Chan - to highlight the dangers of using non-traditional remedies and products. Even more bizzarely, sales of western alternatives such as Head & Shoulders also went up, even though their levels of dioxane had been reportedly higher (and still well within safety limits).

The lack of a concerted product recall or response proved to be disastrous for the share price, despite a defamation case win in May 2016.

Case study #3: Samsonite’s handles

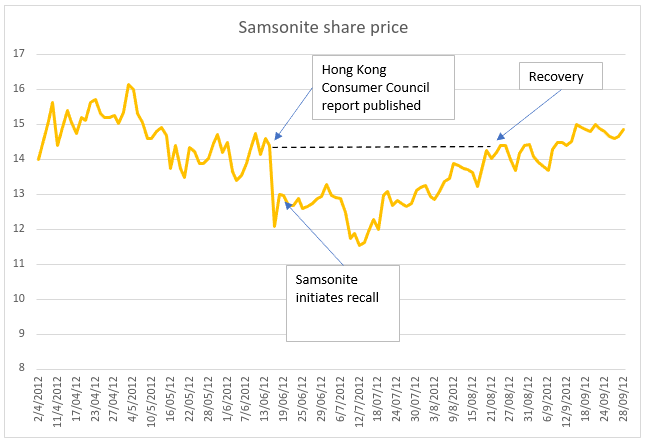

A similar accusation but a very different response and outcome in this final case study.

On 15 June 2012, Samsonite’s “Tokyo Chic” suitcases were accused by a Hong Kong consumer group of having high levels of compounds linked to cancer in their handles. Samsonite recalled 250,000 cases globally on 19 June 2012 despite independent tests showing no health threat. The stock price recovered within a couple of months.

The consumer council reported levels of polycyclic aromatic hydrocarbons at 17,960 milligrams per kilogram. Samsonite's independent tests found levels of 17 milligrams per kilogram or as Ramesh Tainwala, Samsonite's Asia Pacific and Middle East president put it "A human being has to eat 100 handles and then you have the probability of one in a billion chance of getting cancer."

Conclusion

A company’s value chain is inexorably connected to its success. An efficient supply chain can be as important as outstanding product innovation - look at the relative successes of Nokia in handsets during the early 2000s and Apple in more recent years.

It is important for businesses to have, and for investors to understand the governance around the supply chain and the processes in place for addressing issues within that supply chain from both an operational and a communications perspective.

Both can have material impacts on value.

Something a little more bespoke?

Get in touch if there is a particular topic you would like us to write on. Just for you.

Contact us

Please read: important legal stuff.