The cheapest energy is the energy you don’t use

The cheapest and greenest energy is the energy we don't use. And this is especially true in industry, where energy waste reduction can result in real financial gains. Plus benefits to the planet and wider society.

The cheapest and greenest energy is the energy we don't use. And this is especially true in industry, where energy waste reduction can result in real financial gains. Plus benefits to the planet and wider society.

We all know that a lot of our energy is 'wasted'. That there is a big difference between the total energy we produce (primary energy) and the amount that actually gets usefully used.

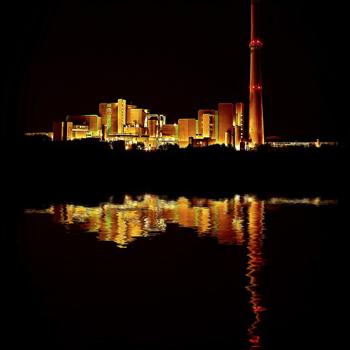

Most industrial processes vent a lot of energy (mostly heat) into the atmosphere, energy that is not used for something productive. If we can use this energy, via processes collectively known as waste heat recovery, then we need to produce less (and pay for less) in the first place.

We have discussed this idea before in the context of home and building heating & cooling. Today we want to start thinking about industrial waste energy. One massive challenge in industrial energy efficiency is its complexity. But just because something is difficult to understand, doesn't mean we shouldn't try.

And the potential big win - it's finding ways of using lower temperature waste heat, we have a lot of this and nearly all of it goes straight into the atmosphere.

This is a What Caught Our Eye story - highlighting reports, research and commentary at the interface of finance and sustainability. Things we think you should be reading, and pointing out the less obvious implications. All from a finance perspective.

It's free to become a member ... just click on the link at the bottom of this blog or the subscribe button. Members get a summary of our weekly posts, including What Caught Our Eye and Sunday Brunch, delivered straight to your inbox. Never miss another blog post !

Heat Transfer Research Inc (HTRI) held its 2024 Horizons Symposium recently on the topic of Utilization of Low-Grade Waste Heat in Industry. I have to be honest, most of the papers presented were much too technical for me, but the opening remarks by Thomas Lestina, their senior vice president engineering, started me thinking.

He made two key points. The first is that waste heat recovery has been used to reduce costs for energy intensive processes for decades. This is a known and well proven science. But, although the design of heat transfer equipment and processes are well established, improvements have historically only been gradual. The shift to sustainability is changing this, engineers are increasingly looking at pushing the existing boundaries. Which is good news.

And his second point was that we already have proven applications for higher temperature heat, over 250C. Waste heat at these temperatures, from flue gas and produced gas, can be used to generate steam for facility heating and electric power generation. At flue gas temperatures greater than 250 °C, the efficiencies of waste heat recovery units are usually greater than 85%.

But, things get a lot more challenging at lower temperatures, and so waste heat is rarely utilised. While it is tempting to consider outlet cooling water and cooling air as a heat source, it is rarely done.

This same point was also picked up in a recent McKinsey study - Waste not: unlocking the potential of waste heat recovery. They make the point that low natural gas, electricity, and CO2 prices have meant that there has been limited incentive to push waste heat recovery to the limits. Many projects had long payback periods and using waste heat recycling techniques to improve energy efficiency was not a priority. But that is changing.

Heat-to-power technologies have advanced, including the organic Rankine cycle (ORC) that can recover waste heat from lower temperature sources and convert it into electricity. As with many similar technologies the main cost reductions have come from modularisation of equipment and the standardisation of design.

This theme was also picked up in a recent Brunel University study noted that in the UK 70% of final energy usage in the industrial sector is for thermal processes (furnaces, reactors, boilers and dryers), and up to a third of this energy is wasted through losses.

But, the vast majority of this energy, is available at low temperatures, below, 90 C, which makes it difficult to use directly within the plant or converted economically to electrical power using currently available technologies.

They looked at developing an innovative heat to power conversion system capable of recovering and converting low temperature waste heat to electrical power at competitive efficiency and higher thermal to electrical energy conversion ratio than currently available technologies. Although this is not yet commercialised, they believe that the innovation potential and impact of the system are significant.

But, waste heat can also be used for applications outside of the industrial plant. And the easiest one is space and hot water heating for buildings. This was the topic of a recent technology review, published in Science Direct. This was titled 'Evaluation of low temperature waste heat as a low carbon heat resource in the UK'

Outside of using waste heat to generate electricity, recovering low temperature waste heat generally involves transferring the heat to water, which is then upgraded to a desired temperature using heat pumps, before distributing the heat recovered using a local (or district) heat network.

The problem was that traditionally, heat networks operated with high temperatures (so called 1st to 3rd generation networks), and upgrading low temperature waste heat to the network temperature was not considered economic. However, the advent of lower temperature 4th and 5th generation (4G and 5G) networks has greatly increased the opportunities for recovering low temperature waste heat. 4G systems work at supply temperatures of 50–60 °C, and 5G networks, which are often termed ambient loops, typically operate with supply temperatures of 15–25 °C.

These advances mean that using waste heat from industrial processes for district heating is now viable.

Looking at this from an investment perspective, while generating electricity from lower heat waste is something to watch, its use in building and hot water heating looks like it has greater potential. This is something we will come back to in future blogs.

Please read: important legal stuff.