Sunday Brunch: the world is not linear ....

Yes, we need to prepare for the future, but in a resilient way. One that doesn't lock us into 'the future will look like the past'. And that includes mining for critical minerals.

One negative about the way that many people value companies and investments is that it encourages us to treat the future as a known, and to believe that future outcomes will likely turn out to be close to some sort of central forecast. The reality is very different. Real world outcomes will probably look very different from our forecasts, especially once we get out five years or more in the future, which is where most value is created.

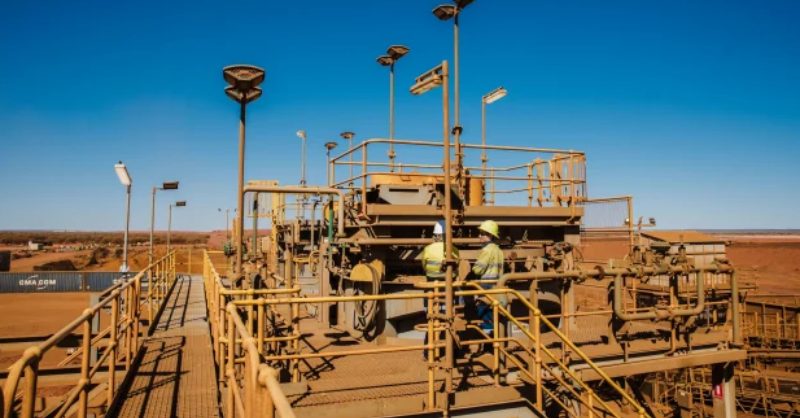

I was reminded of this when I read a recent S&P Global blog on how long it takes for a mine to be developed, from initial investigation through to full output and commercialisation (it's 15.7 years by the way). Don't get me wrong, this was a very useful piece of analysis, but before acting on it we need to decide if the future will look like the past, if will we end up demanding the same raw materials in ever increasing quantities. Or will we find different approaches to production?

Which brings me to resilience. I think this is something that we don't talk about enough in relation to companies. When we know that the future is going to look very different from the past, but we don't know exactly how & when (uncertainty), we want the companies we are invested in to be prepared. To have plans that prepare them for the various outcomes. If the company you are invested in thinks everything is just going to carry on as normal, maybe you need to test their logic just that bit harder!

And before I let you go, you may have spotted that we had no What Caught Our Eye blogs this week. Unlike nearly all of Europe, I am taking my holiday in September, so a reduced publication schedule for a few weeks.

It's free to become a member ... just click on the link at the bottom of this blog or the subscribe button. Members get a summary of our weekly posts, including What Caught Our Eye and Sunday Brunch, delivered straight to your inbox. Never miss another blog post !

Discovery to production averages 15.7 years

A really interesting blog from S&P Global estimated that the average lead time from discovery to commercial production for new mines was 15.7 years. The implication is that a mine project starting now could be fully up and running by around 2040.

They calculated this based on mines that began production between 2002 and 2023 and were discovered from 1980 onward. In other words, they didn't include mines that didn't end up reaching commercial production. So the 'real' time to commercial production could be longer.

A couple of things initially leapt out at me. The first was that certain critical mineral mines, such as for copper and nickel, took longer than the average, by about an extra year or so. And the second point was that the vast bulk of the time was taken up studies, discovery and exploration. For the average mine that contributed 11.9 years. This would include permitting.

And then I started thinking about how the future might look different. And how the future demand projections we are using might benefit from some context.

How might the future look differently?

One way the future could be different is obviously more recycling. We already recycle a decent amount of copper, but recycling for some other minerals is really only just getting off the ground.

But that is not the only way that we could 'meet' future demand. We could also redesign the product, dramatically changing what raw materials we use. This report from RMI covers how the future for battery raw minerals might look different.

One redesign example is the shift in battery chemistry from what is known as nickel manganese cobalt (NMC) to lithium iron phosphate (LFP). While NMC still offers better energy density (more power and/or range), LFP is making a major comeback thanks to its safer, more accessible materials and improving performance. You don't need to understand battery chemistry to spot that LFP batteries do not contain cobalt.

A good description of this trend, and some issues it raises for western countries, can be found in a recent podcast from Volts.

This could all mean that some of the short falls in critical mineral production might turn out to be less serious than it first appears.

But, despite this, we know we are likely to need some more mines. And as the S&P Global blog illustrates opening new mines takes time. Often a long time.

There is much talk that to get more mining to happen, we need to relax regulations. This is also problematic. The industry relies on social licence to keep operating, and relying on the top down imposition of solutions may create short term gains, but it could turn out to be counter productive. Legal challenges and public protests can delay a project for years. More trust in the mining companies could help to resolve this.

Coming full circle back to resilience.

As investors, we need to understand how the companies we finance are preparing for these changes. And the only people who can give us the information we need are the companies themselves, through their financial disclosure.

It's not enough for them to say that they are committed to net zero, even if this commitment includes scope 3 emissions. We need to know how they are going to deliver this 'promise', and what assumptions they are using. If they are assuming no change (which some companies seem to be), or if they are relying on an unproven technology, they need to explain how this would work. And we need to know how their strategy is backed up by real investment, not just hopes.

One last thought

Future critical mineral demand doesn't only come from the sustainability transitions. What happens in other industries also matters. Take copper as an example. According to the 2024 IEA Global Critical Minerals Outlook, 2023 copper demand totalled 25,855 kt, of which 6,311kt (or c. 25%) came from cleantech.

They estimate that by 2040 total demand will have risen to 36,379 kt, with cleantech making up c. 45%. But, they also estimate that total secondary supply and reuse will have more than doubled to 11,006 kt. So total virgin supply doesn't have to rise by anywhere near as much as the demand figures suggest.

And this assumes no change in copper usage among the other big demand groups, such as construction.

Context is important. Remember this when people talk about cleantech demand for copper nearly tripling by 2040.

Please read: important legal stuff.