The simple and the ancient

The built environment is a key decarbonisation and health & well being problem. Whilst new technologies will be key, ancient approaches can inspire modern investible equivalents.

“The future is already here – it is just not evenly distributed.” William Gibson 2003

Summary: The simple and ancient often works. In many cases we need new solutions, but sometimes it should be more a case of applying what we already know, just much more widely. Sometimes, this “known” technology has been around a long time. Nowhere does this logic apply so aptly as in our built environment, the physical landscape that makes up our cities. We shall look at opus caementicium, Chaudes-Aigues, dikang, ondol, the hypocaust, and mediaeval tapestry. These ancient approaches led to modern equivalents. Different approaches to concrete production (or more strictly making cement), the use of geothermal, especially for district heating, underfloor heating, insulation, and retrofitting buildings, rather than demolishing them and starting again.

Why this is important: New technologies take time to perfect and implement. We have had thousands of years of innovation that could be deployed now.

The big theme: The built environment is an important sustainability theme, both as an integral part of societal existence but also as a major decarbonisation (40% of energy-related GHG emissions) and resource consumption problem (40% of global raw materials). There are many avenues to decarbonise across all phases of a buildings life: design, construction (and deconstruction or demolition), operations and interaction with other structures and the environment. Reduce, reuse and recycle and circular design principles can be applied to the built environment to reduce its overall environmental footprint and sustainability.

The details

At first glance it might seem odd to look at what we can learn from old and already proven technologies and practices. But it highlights an important point - in our desire to find and roll out investible solutions, do we tend to look too much toward new technologies, and ignore what we know already works.

Among the “known” we already have some interesting and investible solutions to our climate and environmental challenges. Examples include different ways of producing cement, geothermal anywhere for building heating, better insulation, domestic scale underfloor heating using known heat pump technologies and of course, building refurbishment. Some are already rolling out at scale, others just need a “gentle” push.

Have we become too fixated on new and innovative technologies?

Yes, in many cases we need new solutions, but sometimes it should be more a case of applying what we already know, just much more widely. And sometimes, this “known” technology has been around a long time. Nowhere does this logic apply so aptly as in our built environment, the physical landscape that makes up our cities. One challenge, these technologies and approaches often do not make for exciting reading in company results presentations or in broker research. And the companies that implement them are often local, rather than global mega businesses. So often they don’t get the attention they deserve from investors.

What sort of technologies are we thinking of?

Different approaches to concrete production (or more strictly making cement), the use of geothermal, especially for district heating, underfloor heating, all technologies understood by the Romans. Plus, insulation, known about since mediaeval times, and retrofitting buildings, rather than demolishing them and starting again.

Why this is important

The built environment is an important area of focus for sustainability investing. It represents over one third of global final energy use, generates nearly 40% of energy-related Green House Gas (GHG) emissions (which in themselves are 75.6% of total GHG emissions) and consumes 40% of global raw materials.

The earliest known human settlements date from approximately 300,000 years ago and since then we have become more urbanised. It is now estimated that over 56% of the world’s population lives in cities. If humans persist, (which of course we all hope to be the case!), then the built environment will continue to be a necessary part of society: to inhabit, to work, to entertain and be entertained, to be looked after, to research and discover and to create the things that we need to sustain us. Indeed, UN Sustainable Development Goal 11 aims to “make cities and human settlements inclusive, sage, resilient and sustainable.”

It is predicted that by 2050 more than two-thirds of the world population will live in urban areas putting upward pressure on the contribution of the built environment to resource consumption, GHG emissions and ultimately anthropogenic global warming.

Breaking down the challenge

We can think of it in two parts: embodied and operational.

“Embodied” refers to the process of taking raw materials and resources and arriving at a building or facility that is ready for occupation and use. This is energy that is used to extract materials, transport them, and then transform them into useful construction items, remembering that the processes of transformation can produce GHG emissions. In other words, it is the act of creation. I should also include “de-creation” (yes, I know I made that word up), as there are also emissions from the act of demolishing buildings when they are no longer useful. Embodied carbon contributes about 8-10% of global emissions. Compare this with say the total aviation industry, which contributes roughly 2-3%. So, it is an important problem to solve.

“Operational” refers to the consumption of resources when the building or facility is in use. I would further subdivide that into two main areas: “Thermal regulation” or keeping the environment at an appropriate temperature and “Powering activities” or enabling us to do stuff in those facilities like running a washing machine or running a computer to write things like blogs for The Sustainable Investor.

As a former engineering student, it would be remiss of me to not mention some physics, chemistry or maths at this point, so I’ll restate the law of conservation of energy as follows:

Generation = Consumption

or in other words the energy generated upstream is consumed downstream in the built environment. If we can lower consumption, then we can lower generation which in turn should lower harmful emissions (even before we talk about the mode of power generation).

Furthermore, we can subdivide Consumption:

Consumption = Usage + Wastage

or in other words what we use usefully and what is lost to the universe (or used up un-usefully). Usage and Wastage can both be lowered through improvements in efficiency which can be both active and passive, and through behavioural changes (for example, resetting what we assume to be a comfortable temperature). I guess there is a fair bit of that happening across Europe right now, as winter approaches and high gas prices start to bite.

As well as the reduction in emissions upstream, this type of improvement can also make buildings more cost effective to operate and maintain as well as making them more inclusive through better affordability.

Solutions do not need to be complex : the Simple and Ancient.

Solutions to our built environment challenges don’t necessarily need to come from advanced technological innovation. Some are relatively simple, and largely require changes in behaviour, changing how we use things (or in some cases use things properly!). We can also learn a lot from the ancients and of course the 15th Century remake that was the Renaissance. That is the focus of this blog. Let’s look at some examples (by no means an exhaustive list).

Opus caementicium - Roman cement

Most construction today uses concrete with a similar formula comprising aggregate, water and Portland cement. Initially when mixed it is a fluid that can be shaped and formed easily. The cement reacts with the water and it chemically sets over time to form a stone-like material.

Portland cement is predominantly composed of clinker which is produced largely from limestone (CaCO3) mixed with various other compounds. There are various stages at different temperatures, but the final stage creating alite (Ca3OSiO4) requires a very high temperature, at around 1,450 C (2,640 F).

There are two key GHG emissions elements here. Firstly, the combustion of fuels to create that required heat. Electrification of cement production is one way to reduce that footprint with a number of projects underway or being investigated including Coolbrook collaborations with Cemex and Ultratech.

Secondly, the decomposition of limestone releases carbon dioxide:

CaCO3 + heat ⇒ CaO + CO2

Carbon capture and storage of emitted CO2 from the decomposition of limestone in the clinker production process is another way, although CCS projects more broadly have had mixed results.

However, taking a different approach, if we can reduce the amount of Portland cement in concrete, we can also reduce the amount of CO2 emissions. Opus caementicium or Roman concrete was a construction material used in ancient Rome, that set in the same way as modern concrete but was more durable and crack resistant due to the inclusion of pozzolanic ash and it actually gets stronger over time. It could also be created at much lower temperatures.

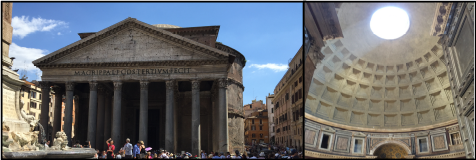

The Pantheon in Rome is a great example of Roman concrete construction. The height of the oculus (the opening at the top streaming sunlight in) is 43 metres, as is the diameter of the dome. How durable is it? The Pantheon was constructed almost two thousand years ago.

And the ancient Roman aqueduct below, just northeast of Nimes in France, was built in the first century AD. So yes. Pretty durable!

Modern Solutions

Modern day examples of reducing Portland cement in concrete include microalgae based cements and hemp-based concretes or “Hemprete” which is believed to be carbon-negative when taking into account the carbon sequestration from growing the crop. Another alternative is to encourage carbonation in the concrete production process, in other words, the absorption of CO2 by concrete which can substantially reduce the embodied emissions. There are a number of companies offering solutions here including CarbonCure and FLSmidth who are also driving an EU Commission funded consortium to accelerate carbonation technologies in the cement industry.

There are challenges in rolling out new technologies at scale, especially when considering the existing infrastructure. For example, can operational kilns be converted without significantly disrupting supply? Can stranded assets be repurposed to minimise the impact on financial returns? Operationally, cement kilns have been used for waste incineration but clearly that is not without controversy most notably replacing one emitting fuel with another! We need to understand that this is going to be a steady process, with either plant replacement when it reaches end of life, or major upgrades, when the cost argument becomes compelling.

Longer term redevelopment of sites is perhaps a more preferable route, such as at the derelict Shoreham cement works. However, demolition and land clearing brings its own problems, discussed later.

As well as reducing the amount of cement in concrete, there are ways to reduce the amount of concrete itself in construction. The Automating Concrete Construction project (ACORN), combines computing, structural engineering optimisation and robotics to design and build resilient structures that use less concrete. The vaulted floor style shown below uses 75% less concrete than a traditional slab floor.

ACORN is a collaboration across the Universities of Bath, Cambridge and Dundee as well as some industry partners including Foster & Partners and Laing O’Rouke and has funding from UK Research & Innovation (UKRI). Rapid roll out is going to need a sustained focus on retraining engineers and making upgrades to building codes.

Heating buildings -ancient Roman and Greek baths, Chaudes-Aigues and Birdsill Holly.

The Romans and Greeks built shrines and baths around hot springs as they believed that they imbued healing and sacred power. The geothermal energy from these hot springs was also used for space heating for buildings. In the 14th century, the commune of Chaudes-Aigues in South-central France started providing heat for houses and the church from thirty natural hot water sources. In the US, in 1877, engineer Birdsill Holly established the Holly Steam Combination Company to commercially distribute heat from a central plant to a group of town buildings.

Modern Solutions

Today district heating systems use a variety of energy sources and often a combination of fossil fuels and renewables. However, efficiencies are gained through economies of scale, removing the need for boilers in individual properties eliminating onsite CO2 (and NO2) emissions. 5th generation district heating and cooling systems distribute heat at near ground temperature with each building having their own heat pumps to extract heat when cold and reject heat when it needs cooling. The Mijnwater system in Heerlen in the Netherlands is an example of a city-level 5th generation system. The grid here operates at between 18 degrees and 28 degrees Celsius whilst the building heat pumps lift that temperature to between 50 degrees and 70 degrees Celsius for in-home space heating (for cooling it can take the grid temperature down to 10 degrees Celsius).

The European Union has more than 6,000 district heating networks meeting close to 11% of its heating needs. Currently in the UK, district heating networks only supply 2% of heat demand, however under a £320 million investment programme, there is a target to reach 15% to 18% of heat generated by these networks by 2050.

Stockholm has an extensive district heating infrastructure with almost 90% of the city’s buildings connected. The network also recovers excess heat from data centres, supermarkets and other businesses who can sell it on an open marketplace. Compare that with the UK which currently has no regulation on waste heat and where it is estimated that the waste heat from buildings and industrial processes could supply 14% of the hot water and heating demand in UK homes. The Stockholm system also uses large scale heat pumps to extract heating and cooling from purified wastewater. This video gives a great overview. Stockholm Exergi, which is a joint venture between Stockholm and Finnish utility Fortum plans to be 100% renewable fuels by 2022.

District heating systems often sit alongside combined heat and power systems (CHPDH) reducing both energy costs and providing great environmental performance. Here is an example of a system in North Greenwich (that keeps me roasty toasty!) operated by Loka Energy:

Installing a district heating system or even a smaller scale community heating system is clearly easier with new build estate construction and can be planned in. Retrofitting however is clearly challenging as existing infrastructure such as roads and other utilities would be disrupted extensively. For large scale residential blocks, storage tanks and other facilities would need to be installed in the basements, although the work required inside the home is relatively straightforward.

Looking at building cooling, Australian researchers have developed a way to use rooftop PV to run air conditioners to pre-cool residential and commercial buildings. The scientists considered the thermal mass of buildings as a virtual battery that could be used to shift or shave peak demand caused by AC systems.

“Pre-cooling means charging the building thermal mass before peak demand onset by reducing thermal mass temperature and then discharging the coolness during the peak period,” the scientists explained. “This is typically done by reducing the thermostat setpoint a few hours before the expected peak period to force the AC to switch on.” By using the surplus PV generation for solar pre-cooling, households use cheap or free electricity to pre-cool the building, which consequently reduces their imports from the grid during peak hours, when tariff rates are expensive.

Underfloor heating - dikang, ondol and the hypocaust

From as early as 5,000 BC, early forms of Manchurian dikang (“heated floor”) and Korean ondol (“warm stones”) were being used for space heating. Hot smoke was used to heat floor stones and hot air was later used in a scaled up system by the Romans called a hypocaust.

Modern Solutions

These were forerunners of modern day underfloor heating. Underfloor heating systems work at much lower flow temperatures than radiators (35C vs 70-90C) and hence are more efficient and cost effective when operating. It works very well with low flow rate technologies such as heat pumps and district heating and tends to more evenly heat a room than other heating systems.

There are a number of pros and cons with underfloor heating systems. They are easier to install in newbuilds than to retrofit (although there are surface mounted underfloor heating systems too), but they do require screed (a type of cement) to cover the heating mats. Not for every situation, but part of a package of solutions.

Not just for decoration - radiant barriers

In an article for Buildings & Cities in May 2022, Robyn Pender, a physicist specialising in the historic built environment, highlighted the use of wall hangings and fabrics in mediaeval times. These wall hangings were more than decorative. They were typically hung on hooks making them removable. She discovered that their purpose was to provide a radiant barrier between the humans and the walls of the building, thereby keeping more heat in. In fact, Robyn also discovered in her research that buildings predating the industrial revolution were often designed to run passively using layout and these fabrics.

Another interesting observation was that with the wall hangings dealing with much of the thermal discomfort, open windows and hence better airflow were possible. This is evident in many pictures of mediaeval settings.

Modern Solutions

Modern day equivalents include reflective and absorbent surfaces, and built-in insulation. Loft or attic insulation is probably the best known and accessible radiant barrier. It is estimated that around 25% of heat loss in a typical home is lost through the roof. Around 35% is lost through the walls. I know from my own apartment, which is modern and has modern insulation and glazing, that I very rarely need to either switch on my heating or turn on a cooling fan. Perhaps I should get a few tapestries up too?

What other issues does this raise?

The scope of this blog was to look at some simple ways and lessons from ancient civilisations in which one can reduce the energy consumption of the built environment and lower its total carbon footprint. There are of course many other solutions to consider. Here are just a few other things to think about that are also in the spirit of small and local in terms of implementation.

Refit and reuse - when buildings are no longer fit for their originally intended purpose, do they actually need to be demolished? Demolition creates a number of problems from health (all that dust), to collateral damage (all that stress), more embodied emissions from removing the debris and even worse, if a new structure is erected, you are creating even more embodied emissions. Citigroup chose not to demolish its 42-storey skyscraper in Canary Wharf and instead opted for a retrofit, thereby saving potentially 100,000 tonnes of embodied carbon.

Also consider modular construction or holistic construction such as that advocated by the Passivhaus movement? Does that enable easier repurposing as requirements change?

Fit for purpose - according to work by Todd Gillespie, Irina Anghel and Jeremy Diamond for Bloomberg, the biggest single use appliance cost is gas central heating. A big factor in that energy usage is incorrectly set up boilers. Michael Liebreich highlights that whilst the ideal temperature to run a condensing boiler at is between 45C and 60C, boilers in the UK are typically installed and set at water temperatures of 75-80C. Why? “Because they want to install a boiler in four hours, not get complaints that the radiators are not hot, and not have to return to tweak settings.” Think about how much energy, cost and emissions could be saved just by setting up gas boilers correctly! There are guides for how individual homeowners can do this themselves including from NESTA. Could we see more low cost trusted advisers emerging such as The Heating Hub or even a decentralised networks of trusted installation teams that can do the job efficiently? Indeed perhaps the notion of heat as a service?

This is clearly a massive topic, and one where investors, typically via local rather than global action, can really make a difference. Some solutions already have investible and listed companies, insulation is one that springs to mind, while others will need new business models. We will be returning to the topics raised here, in future long blogs (I can already think of one on building cooling) and in our Perspectives.

Something a little more bespoke?

Get in touch if there is a particular topic you would like us to write on. Just for you.

Contact us

Please read: important legal stuff.